Processing and production of

labels and seals

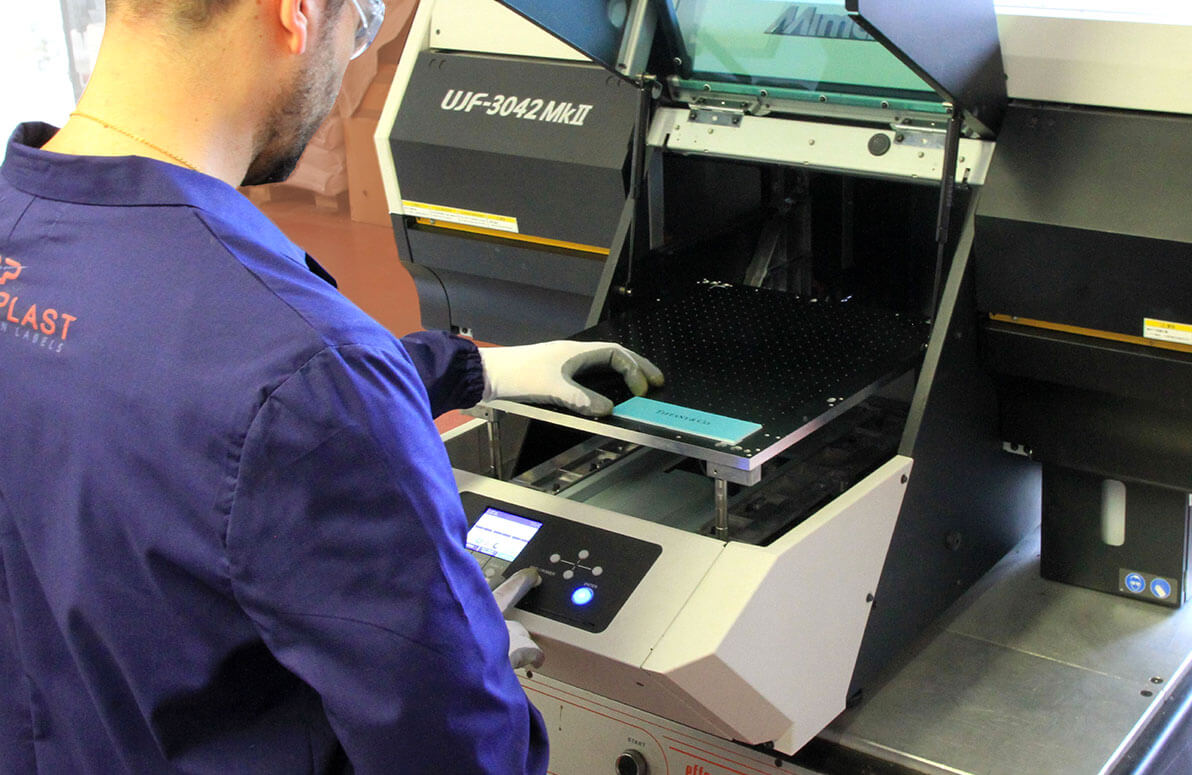

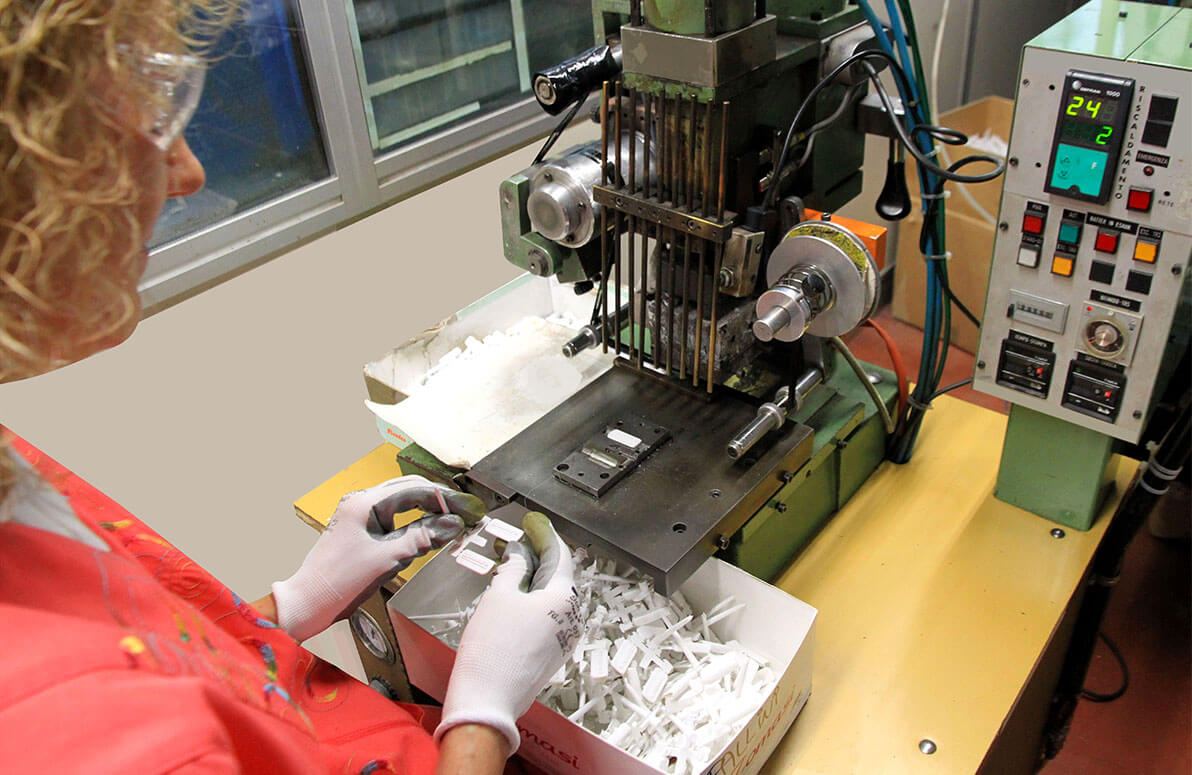

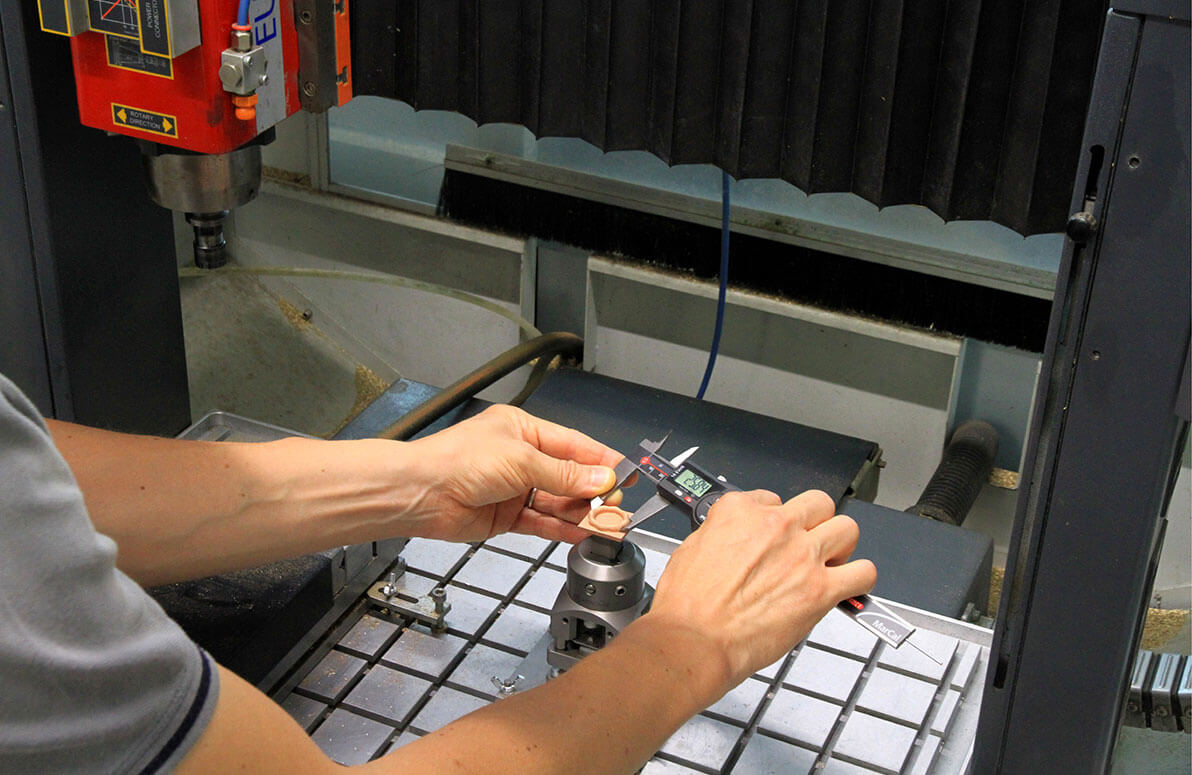

The best customisations for every choice of label

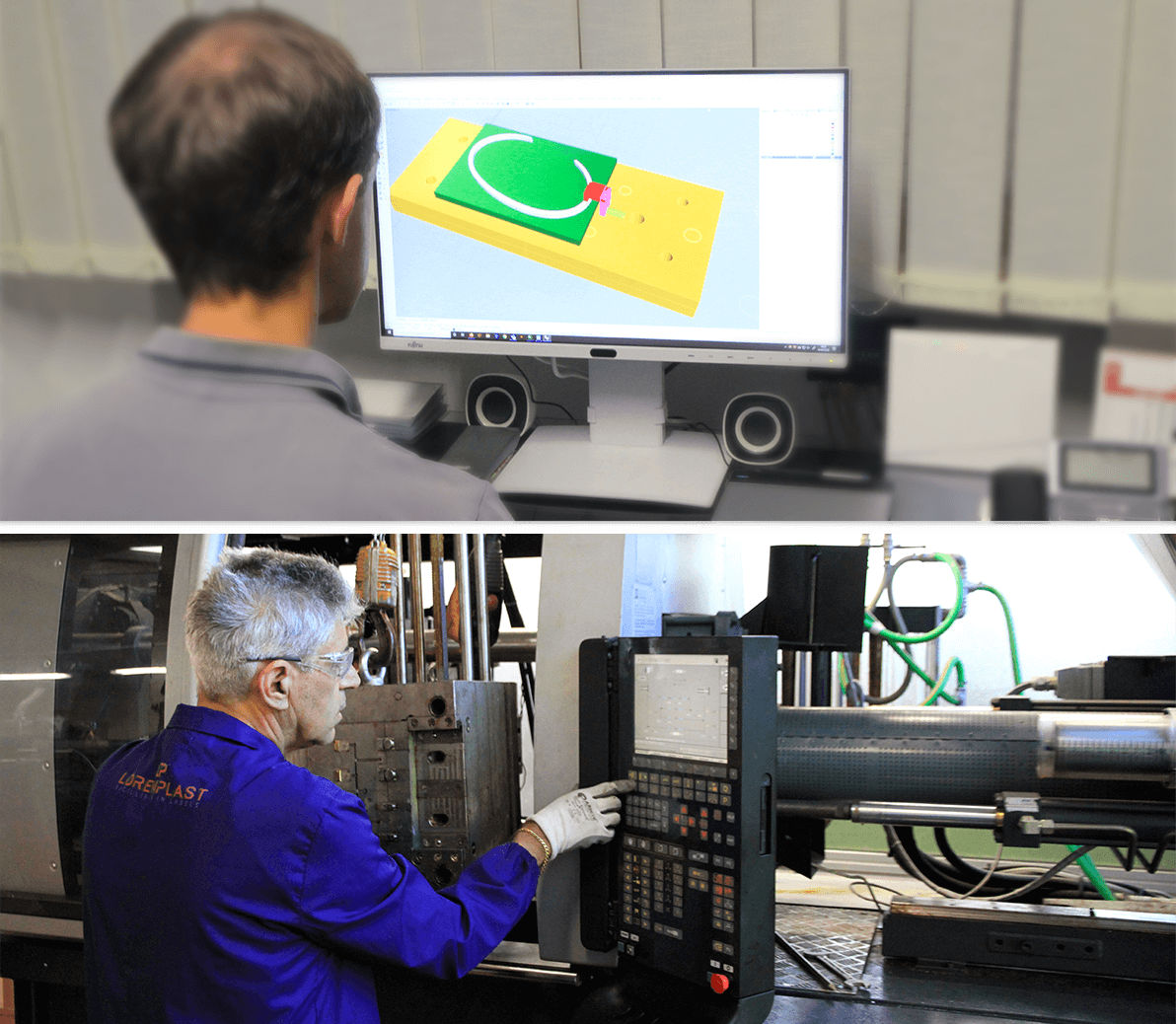

You start with an idea

A combination of ideas produces a unique and personal result. Lorenplast processes each specific request to make it exclusive in the graphics and shape. Each project is followed and processed by a team of designers who transform the idea into a genuine project, offering advice on the types of materials to use, the shapes and colours, to create a label that is in keeping with the message you want to share. Therefore, a graphic draft or a sample with rapid prototyping when the product has a more complex shape is created.